Fusion3

F200 3D Printer

F200 3D Printer

Couldn't load pickup availability

PLEASE ALLOW 4-5 WEEKS FOR PRODUCTION AND DELIVERY.

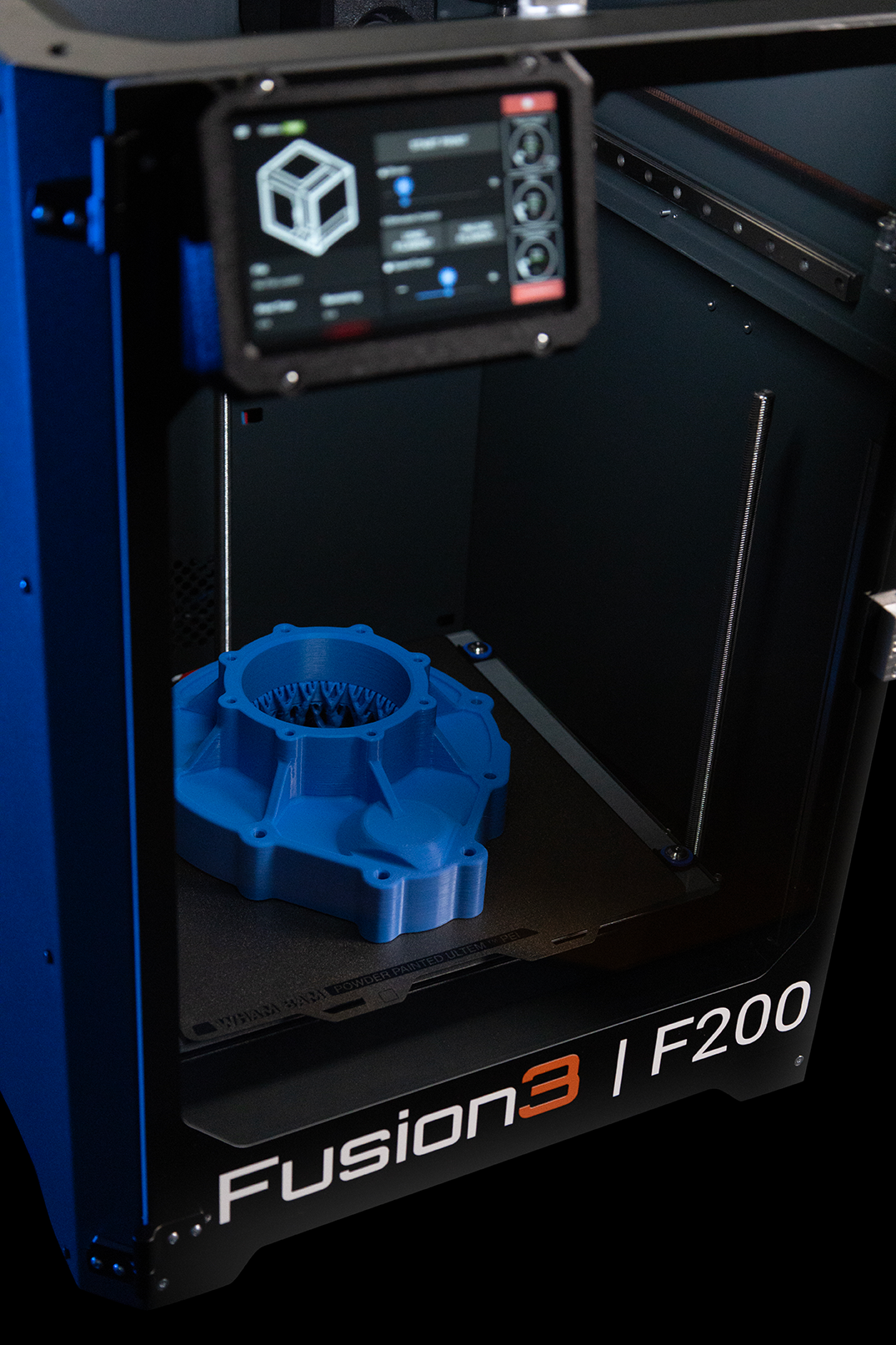

The Fusion3 F200 3D Printer offers professional-grade performance with a max print volume of 256x256x256mm and speeds up to 250+ mm/s. Designed for high-temperature materials like ABS, ASA, Polycarbonate, and Nylon, it ensures secure, offline operation with advanced features like AI print monitoring and emissions control. Built for reliability, the F200 is perfect for advanced hobbyists and small businesses seeking speed and precision.

Build Volume (mm): 256 x 256 x 256mm

Dimensions (DxWxH)(mm): 384W x 475D x 555H

Chassis Type: Steel Skin

Weight: 22 kg (49 lb)

Share

Advanced Capabilities

-

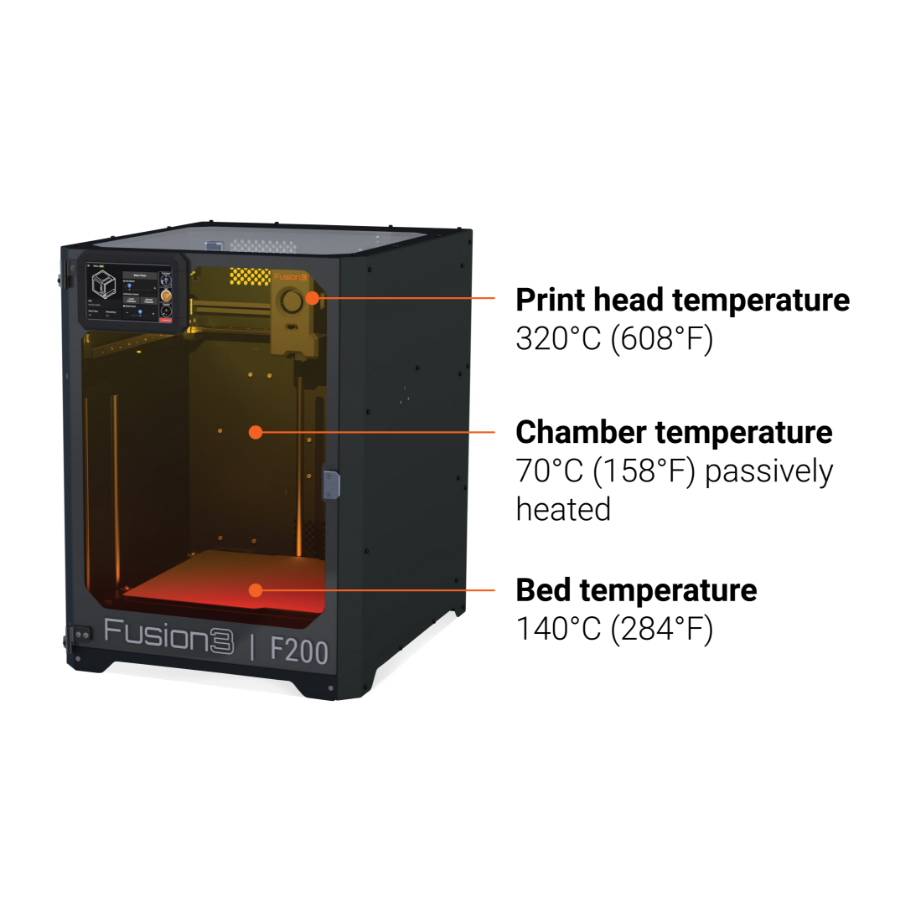

High-Temperature Performance

Withstands a maximum bed temperature of 140°C (284°F), a print-head temperature of 320°C (608°F), and a chamber temperature of 70°C (158°F). The F200’s high-temperature durability makes it compatible with more than 150 engineering-grade materials—far exceeding the limits of traditional hobbyist printers.

-

Security-Focused Architecture

Operates without cloud connectivity services or internet access—ensuring users’ valuable data and intellectual property stays within their local network and on their controlled devices.

-

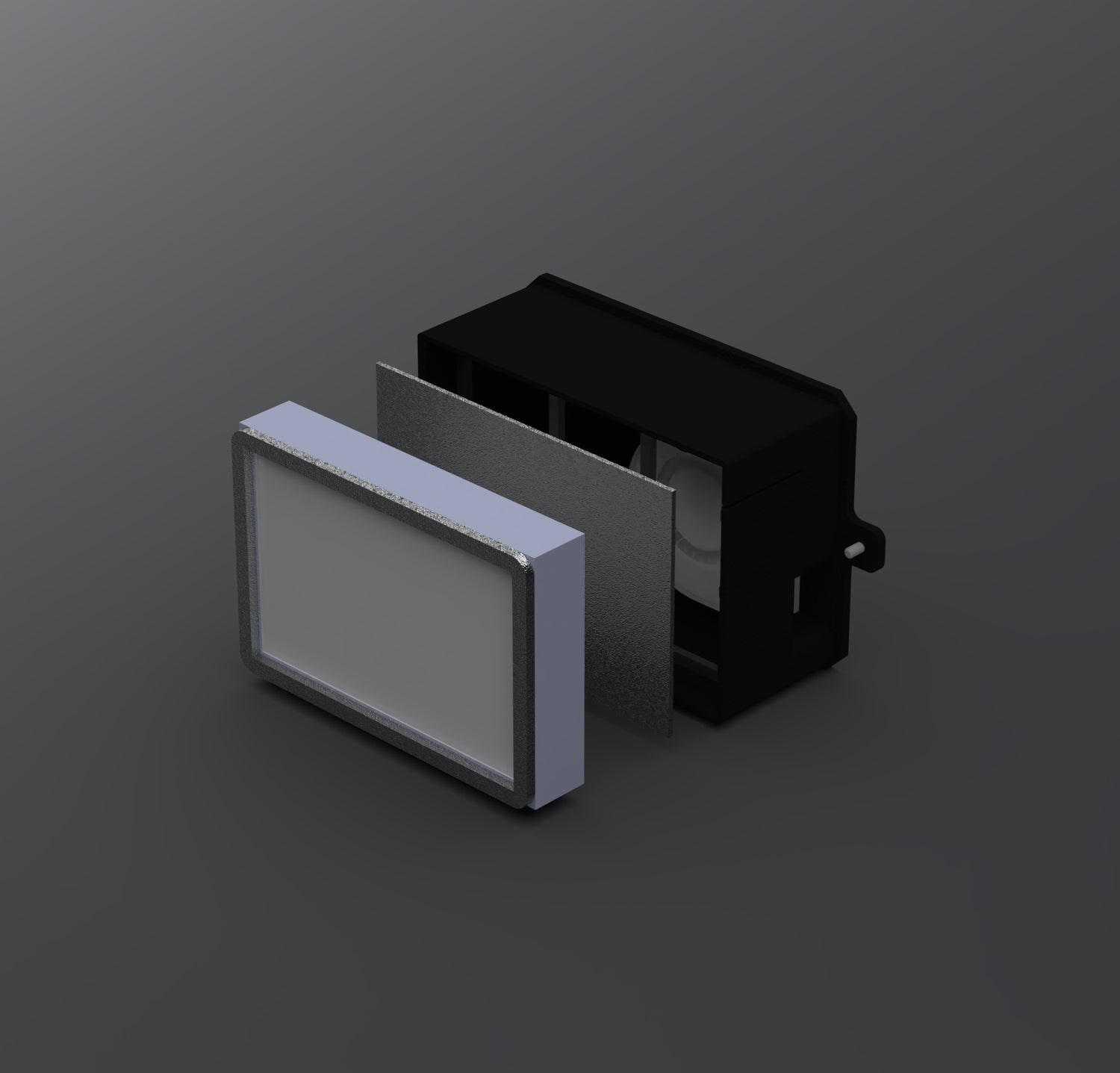

AI Print Issue Detection

Uses an onboard camera to detect issues like spaghetti prints or print lifting, without requiring cloud services or an internet connection. The system can automatically pause the print, or with an internet connection, send notifications of issues when they occur.

The F200 Brings the Heat

Successful prints with high-temperature materials require more than just a high-temperature print head. The bed and chamber must get hot enough to control warp forces and shrinkage while printing.

Unlike consumer 3D printers, the F200’s bed and chamber reach temperature compatible with unadulterated ABS, ASA, and PC.

It is expertly engineered for continuous operation at these temperatures (pictured) with no degradation of mechanical components or performance.

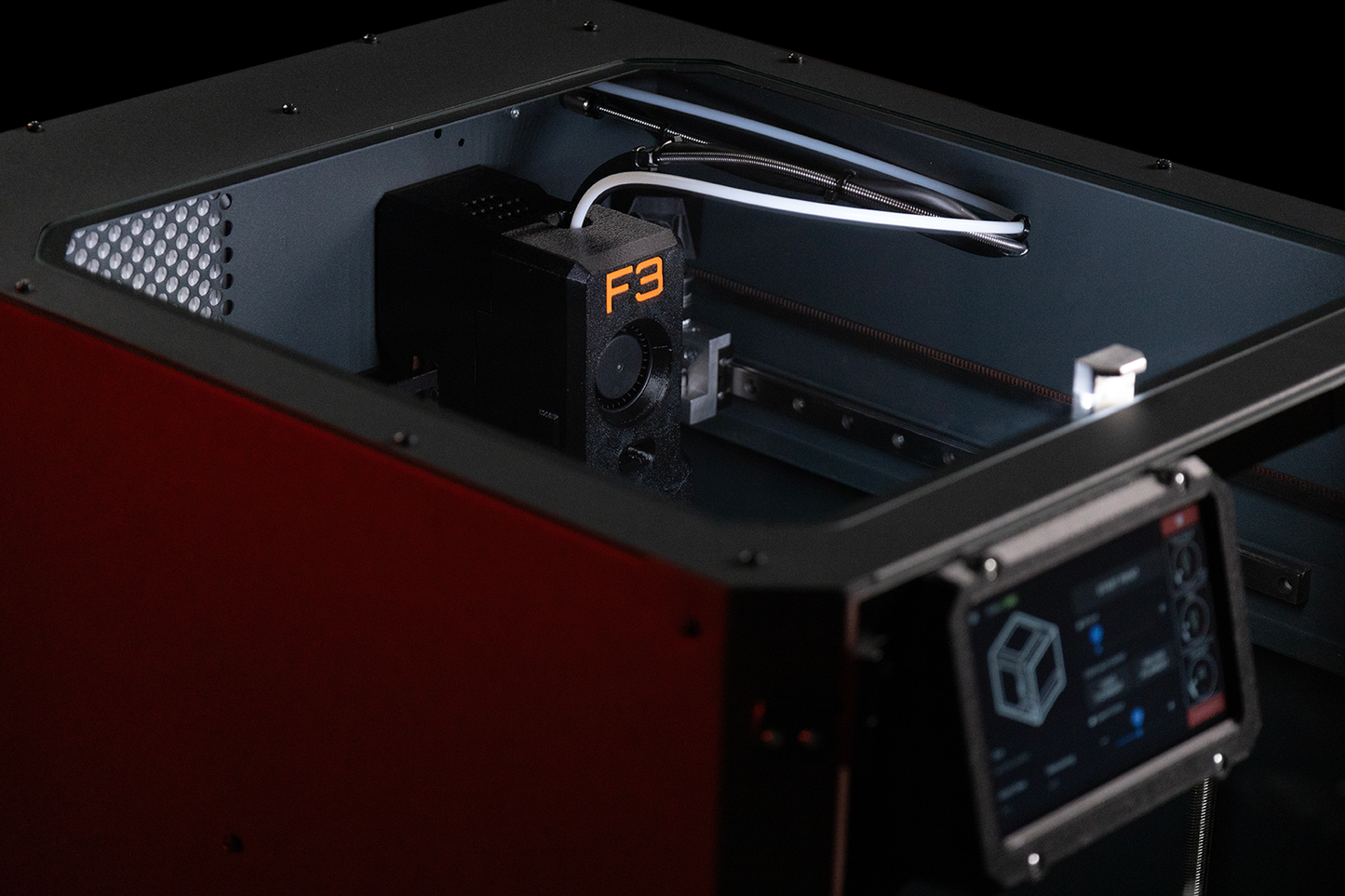

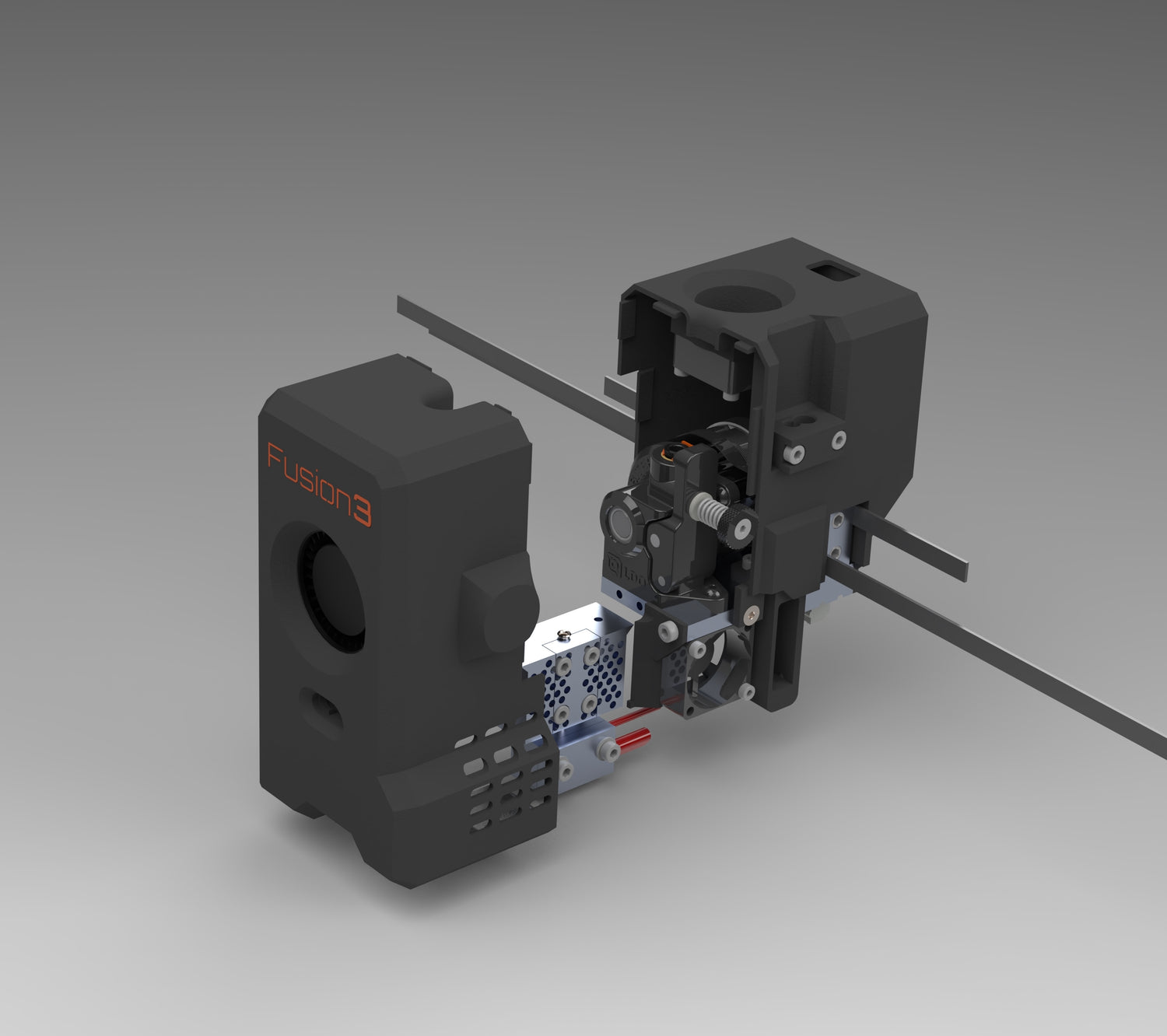

Anvil Print Head

Three interchangeable nozzle sizes

Easy removal from the printer

Leak-free design that resists jamming and clogging

Non-press-fit assembly

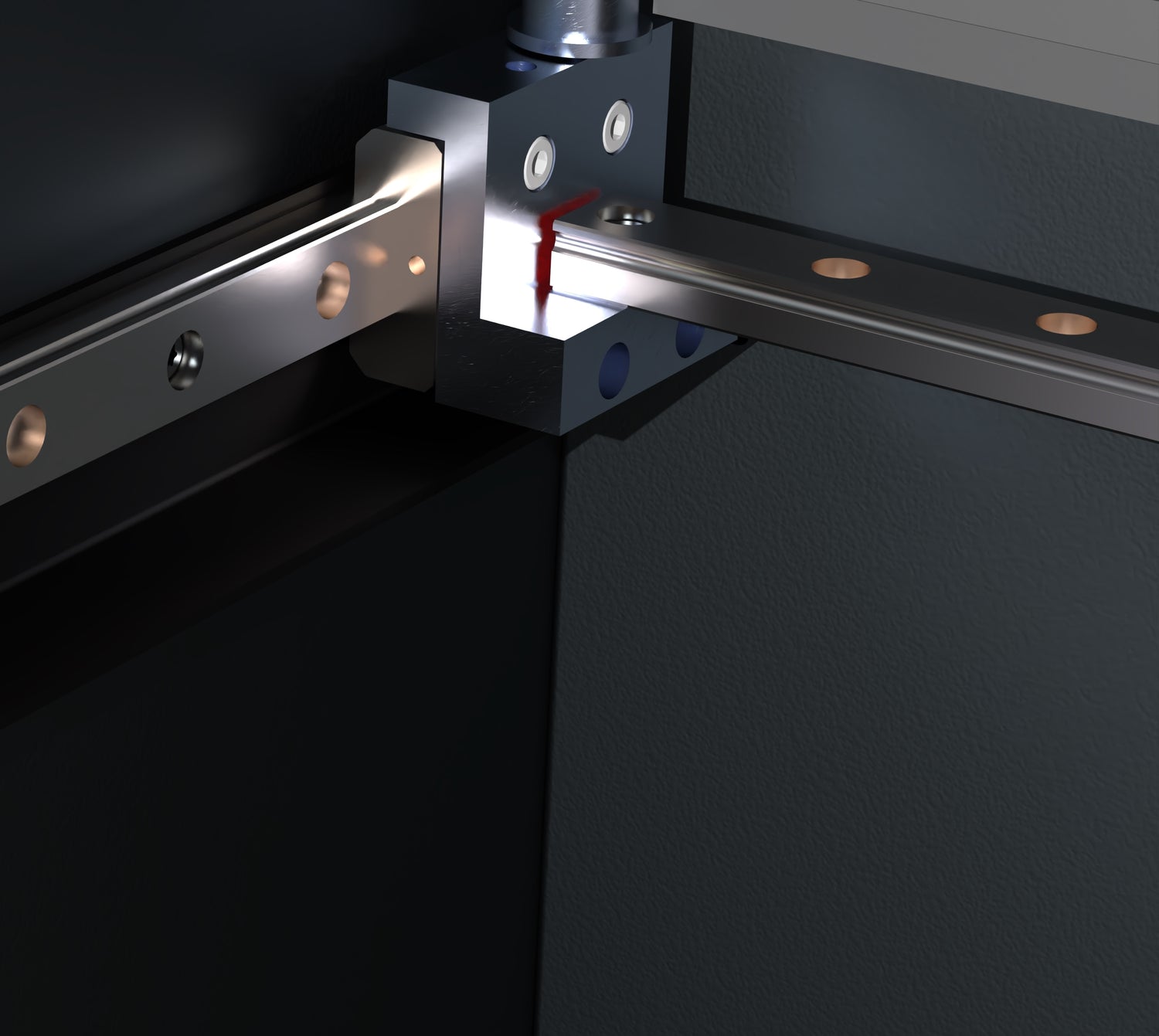

All-Metal Motion Systems

Feature linear rails instead of carbon fiber rods for long-lasting performance

HEPA + Carbon Recirculating Filter

Removes VOC and PM2.5 with 95% effectiveness and passes air through the filter multiple times instead of exhausting it outside the printer

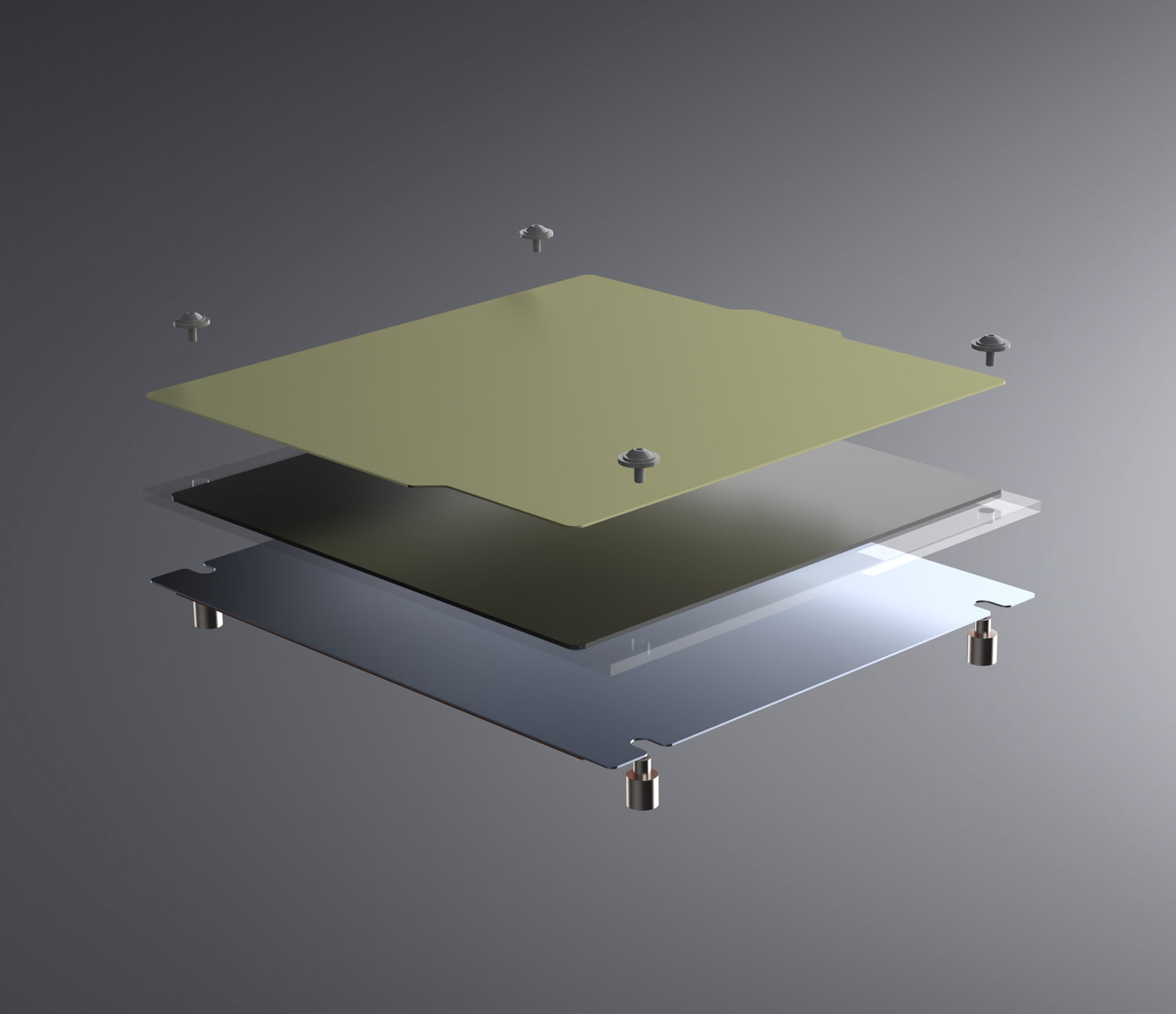

Print Surfaces

The F200’s bed system offers flexibility for printing a wide range of materials:

- WhamBam™ PEI-Coated Build Plate: Durable, compatible with 90% of materials, and allows easy part removal.

- Magnetic Print Base: Supports continuous operation at 140°C.

- Modular Bed Stack: Configurable for materials needing a glass surface.

- Bambu Lab X1/P1 Compatibility: Seamless integration with existing print workflows.